|

|

|

Norlake Manufacturing Company has been providing engineered transformer solutions for over fifty years. Our continued goal is to provide our customers with innovative, cost-effective, and quality engineered design solutions with emphasis on personal service and customer satisfaction. Norlake Manufacturing Company has been providing engineered transformer solutions for over fifty years. Our continued goal is to provide our customers with innovative, cost-effective, and quality engineered design solutions with emphasis on personal service and customer satisfaction.

Norlake is providing cost effective, efficient and innovative magnetics to strengthen our customer’s competitiveness within the market. Norlake’s custom magnetics are designed specifically for your application. You will not overpay for options you do not require, nor will your customers.

Although open to any challenge, Norlake's current design and production capability is comprised of:

- Single-Phase from 50 VA to 700 KVA

- Three-Phase from 50 VA to 12 MVA

- Single & Three-Phase AC inductors to 5000 AMP

- DC inductors to 1000 AMP

- Frequency Designs from 25 Hz to 20K Hz

- Voltages to 15 KV in UL approved Insulation, or higher non-UL

- UL Insulation Systems Class “A” through “S”

- Vacuum & Pressure Impregnation Processes

- Sheet Metal Fabrication / Structural Metal Fabrication

- FEA Simulations

- 3-D Modeling Capabilities

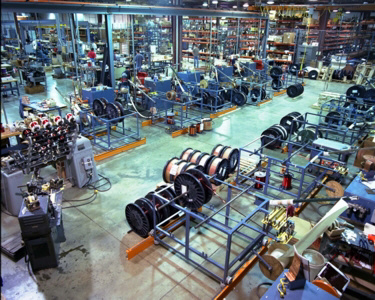

With our expansive production areas, Norlake is able to produce transformers on a scale few others can

Summary of Equipment:

- 16 winding machines with Brake or Friction Tension

- 4 Electrical Steel cut-to-length machines, 1 with hole punching capabilities

- Primary electrical resins Ripley 468-2FX epoxy 8’ Diameter VPI tank, Dolph BC-346-A 10’ x 8’ x 8’ tank and CC-1105 Poly 4’ Diameter vacuum tank. Many other materials available

- 7 Walk-in ovens, 2 smaller ovens

- 20-Ton Crane, 10-Ton Crane, six 2-Ton and two 1-Ton Cranes

Norlake Testing:

- 2 MVA Power capabilities for all your testing

- Phenix Test System for 3-phase and 1-phase testing (solid state with variable frequency) needs

- Induced Testing

- Capacitor Bank for Power Factor Correction

- Standard Testing per IEEE and IEC requirements

- Partial Discharge Testing per IEEE and IEC up to 15 KV class

- Impulse Testing to 200 KV per IEEE and IEC

- Water Flow and Pressure Drop Testing

- IEEE: C57.12.01-2005, 12.91-2011

- IEC: 60076

- NEMA: ST-20

Contracted Third Party Testing:

- Underwriters Laboratories, CSA, CE

- KEMA

- Entela

- Shock & Vibe

- Water Testing

Markets Served:

We Service almost every Market, every Industry Including:

| • Air Ground Power |

• Military / Nuclear Navy Power |

| • Stud Welding |

• Power Conversion |

| • Medical |

• Transportation Rail |

| • Oil Industry |

• Uninterrupted Power Systems |

| • Drives |

• Nuclear Power |

| • Machine Tool Industry |

• Lighting Systems |

| • Wind Energy |

• Mining |

| • Solar Energy |

• Industrial Furnace |

| • Load Banks |

• Airborne Power |

|